DonCorson

[AHCI]

3358

A regular Sunday in the watch smithy.

Jocke posted this as a reply to my BaselWorld 2013 - GoS (Gustafsson & Sjögren) Watches post, but I find it so good I think it needs a entry itself. Enjoy

A regular Sunday in the watch smithy.

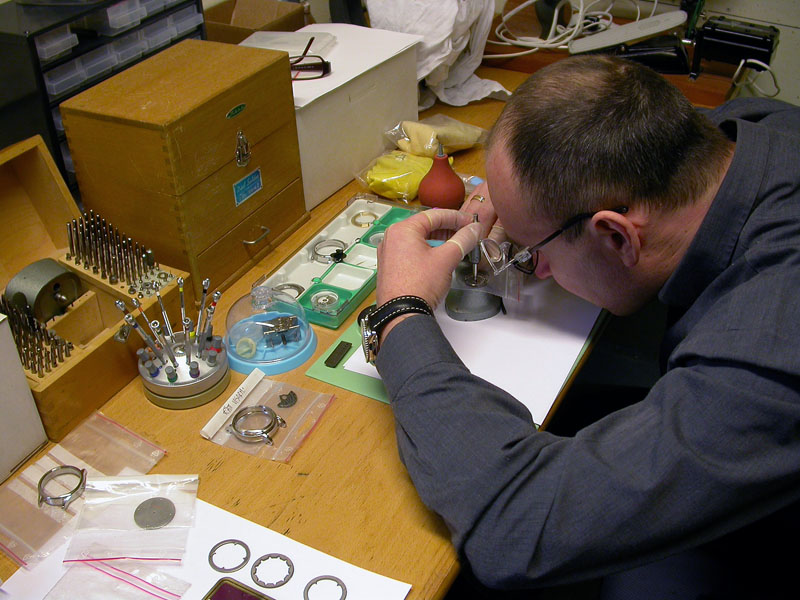

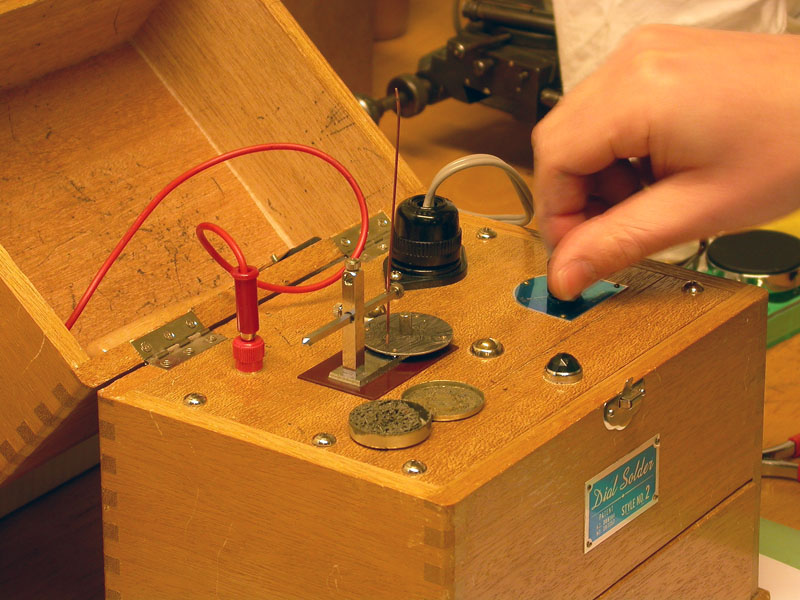

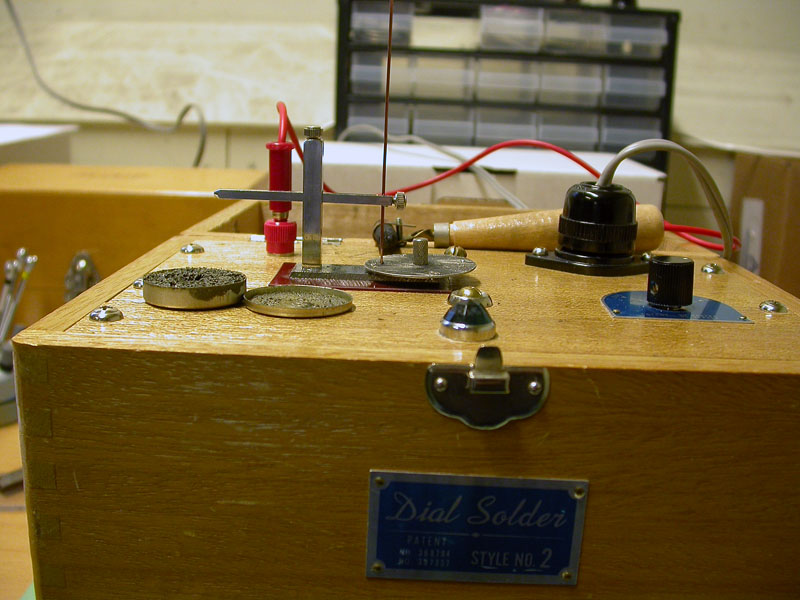

Here we can see the watchmaker Patrik Sjögren with his today special set up at the smithy.

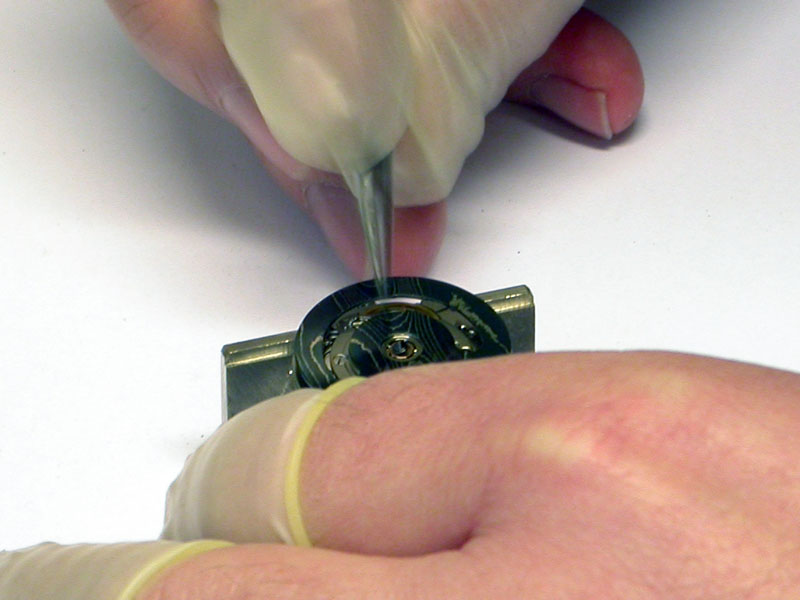

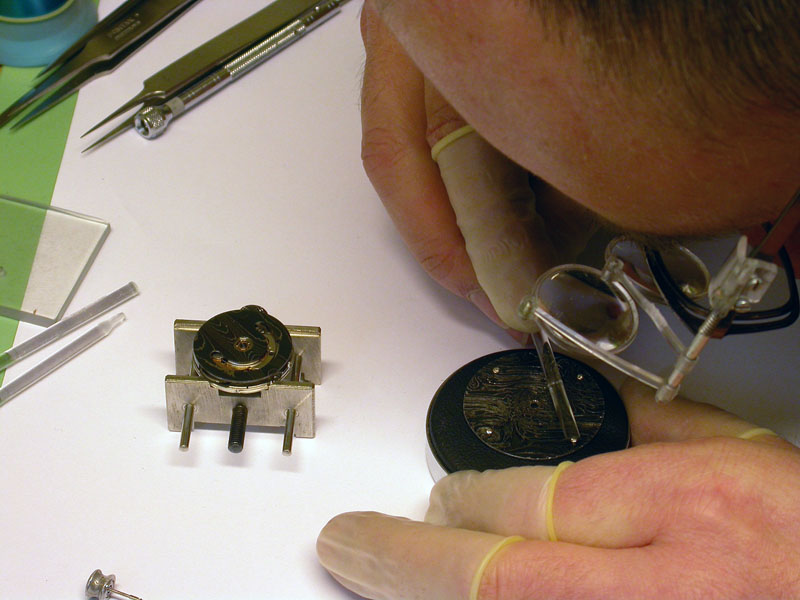

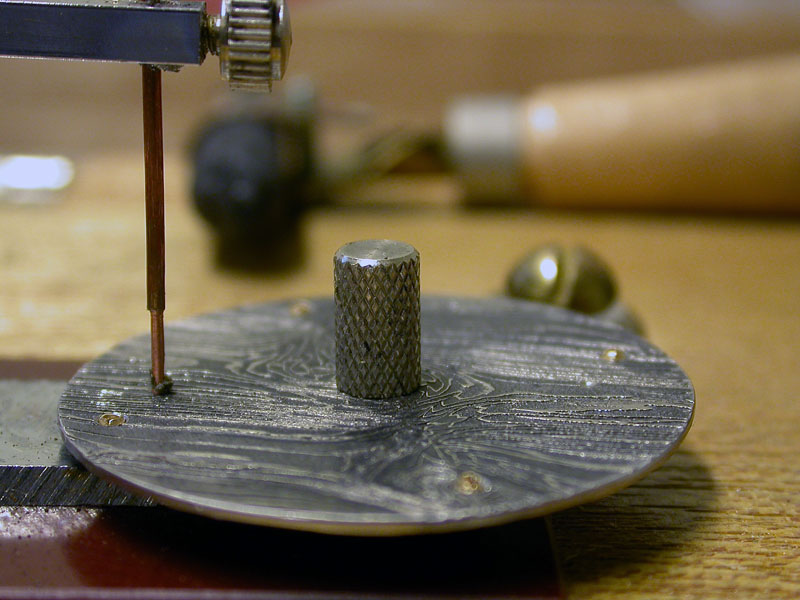

One of their inhouse rotor will be in place..

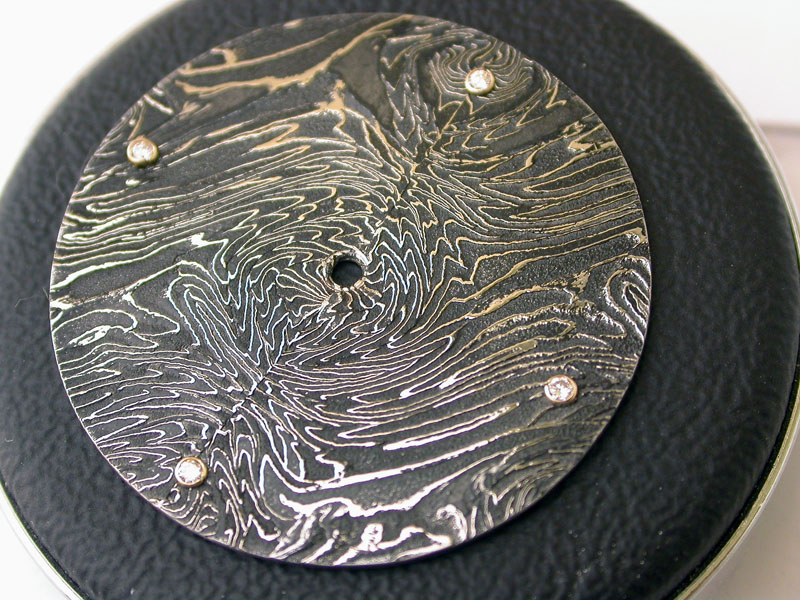

A new dial.

Checking out the diamonds.

A new spacer ring made of metal.

A new case ca 44 mm with 22 mm lugs.

The movement that will be in the case.

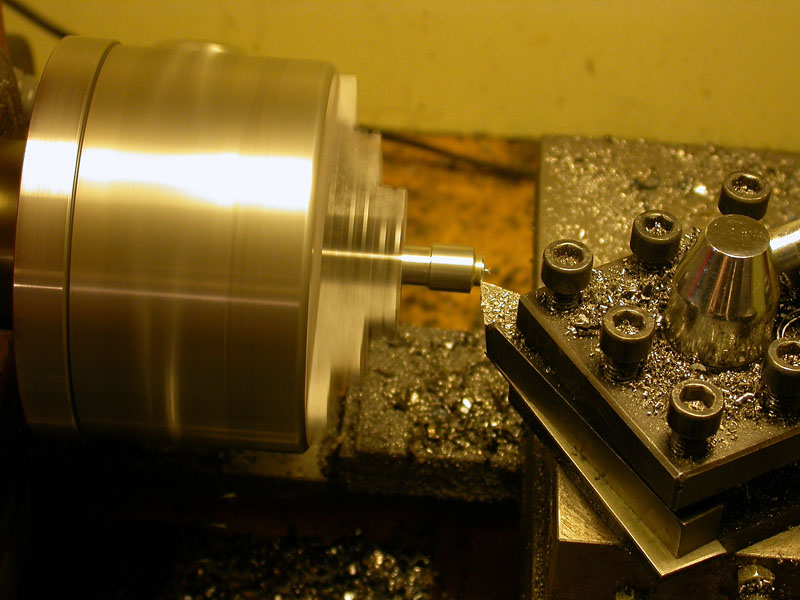

The case in the lathe for some minor adjustments beore the final outside finish.

Here a new crown will be made.

Here is how a dial can looks.

The soldering machine.

The dial solder is to sold the dial feet, then they can get their dials fits in different movements.

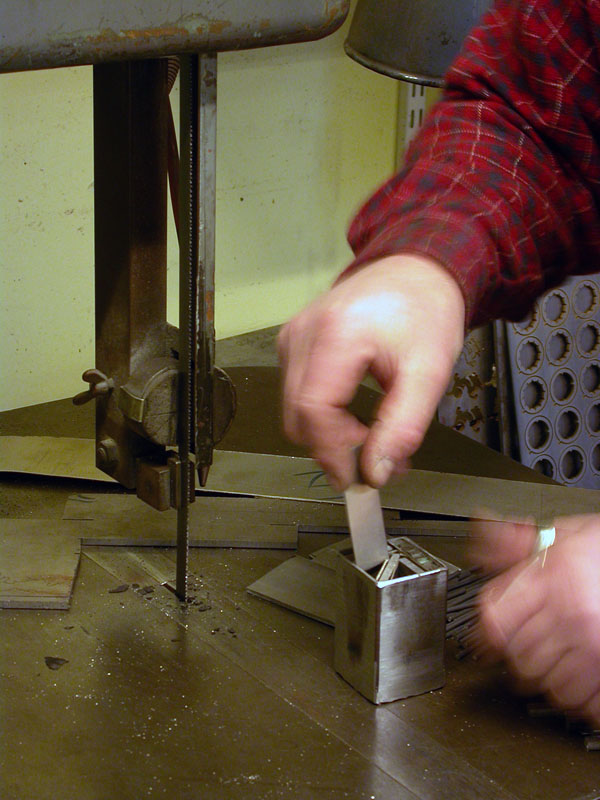

Now we will look at knifemaker Johan Gustafsson's work.

He start to put in some different metals.

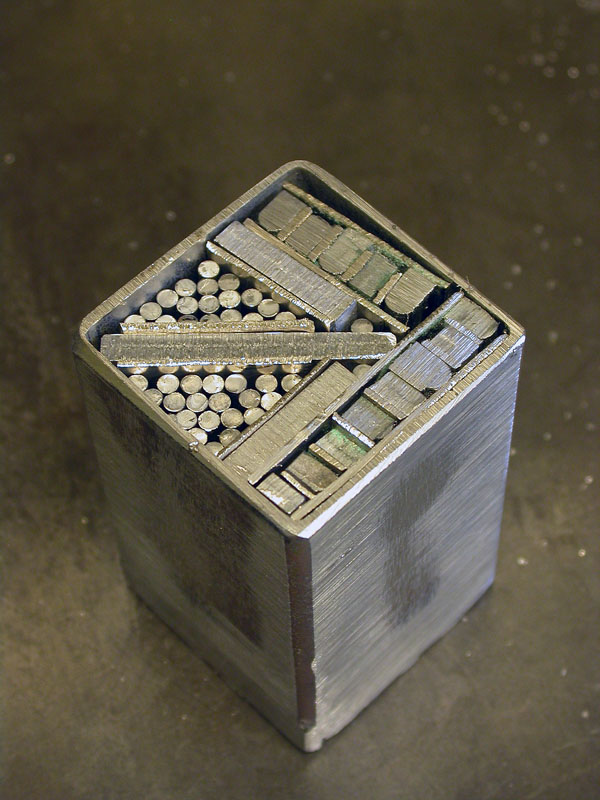

There are no limit how the pattern can looks.

Ready to rock as we use to say.

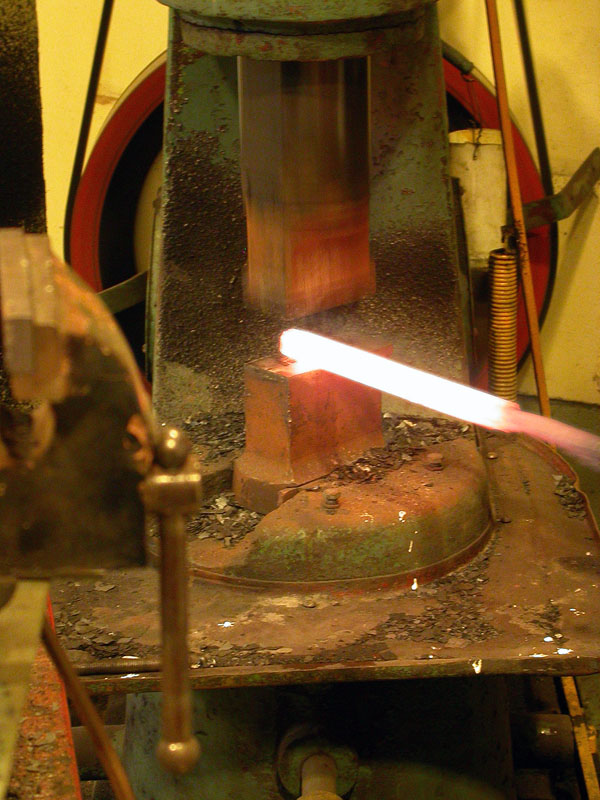

The oven is hot.

And there we go.

Now start working with the hammer.

Now time for the airhammer.

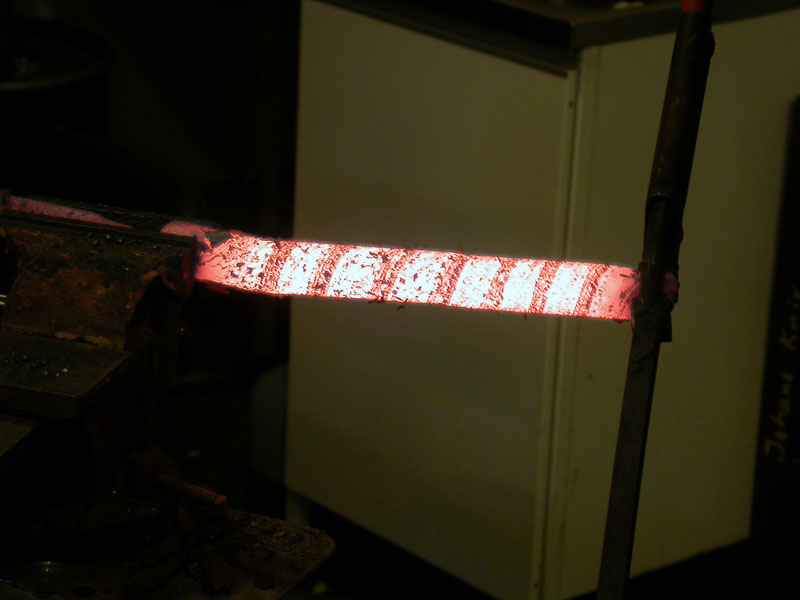

And it will be longer and thinner.

Now it start looking good.

Then it's possible to twist it.

Back to the one we start with as it cold now.

Here is how the end looks.

Now it's time to cut it in 4 pieces.

Now you can choose how the pattern should looks.

Here the parts are together forged.

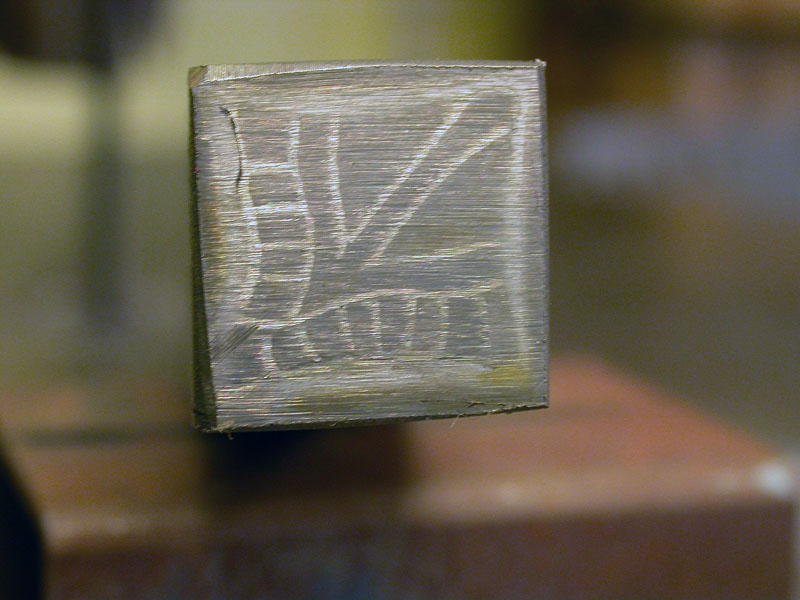

Then it will be interesting to see whats under the raw surface.

The final result.

Then it's just to slice a bit, turn it round and drill a hole and you have a unique dial.

Here is the result of it.

Here it's cutted one more time.

And the same pattern but with less colors.

And some other style.

A regular Sunday in the watch smithy.

Scrolling down...